![\includegraphics[scale=0.6]{mesh1dorig.eps}](img194.png)

![\includegraphics[scale=0.6]{mesh1ddisp.eps}](img195.png)

|

In order to apply the cohesive element pre-stretching at the time of insertion, we must determine the nodal displacement jump across the cohesive surface to be introduced. A relatively straightforward approach to accomplish this is to enforce local equilibrium on the assembly composed of the cohesive element and the adjacent volumetric element. To demonstrate this idea, let us consider the simple 1-D system shown in Figure 2.18.

The local equilibrium equations for the four nodes involved in the cohesive element insertion can be written in the form:

| (2.28) |

|

(2.30) |

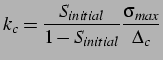

The cohesive node stiffness ![]() is given by

is given by

|

(2.31) |

The nodal forces,

![]() and

and

![]() acting on

nodes 1 and 3, respectively, quantify the existing stress state on

volumetric elements

acting on

nodes 1 and 3, respectively, quantify the existing stress state on

volumetric elements ![]() and

and ![]() . Prescribing the nodal displacements

at nodes 1 and 3 as those computed at these nodes at the time of

insertion, we can readily solve the resulting 2-by-2 linear system in

terms of

. Prescribing the nodal displacements

at nodes 1 and 3 as those computed at these nodes at the time of

insertion, we can readily solve the resulting 2-by-2 linear system in

terms of ![]() and

and ![]() :

:

![$\displaystyle \left[\begin{array}{cc} k_a+k_c & -k_c \\ -k_c & k_c+k_b \\ \end{...

... = \left[\begin{array}{c} k_a u_1 \\ k_b u_3 \end{array}\right] \vspace*{0.5cm}$](img214.png) |

(2.32) |

While this method is quite simple in 1-D and for a single cohesive element, it is quite more cumbersome in 2-D and where a large number of elements are inserted simultaneously. A simpler method inspired from the pre-stretching approach consists in using the local stress field directly to compute, with the aid of the traction-separation law, the initial displacement jump to be applied across the cohesive surface.

Inverting the traction-separation relation introduced earlier, the displacement jump can be written as

The applied cohesive traction, ![]() , is simply chosen as the average of

the nodal internal forces applied on nodes

, is simply chosen as the average of

the nodal internal forces applied on nodes ![]() and

and ![]() by the

volumetric elements a and b, respectively. As shown in

Figure 2.19, the separation is then applied

evenly in both directions from the current location of the original

node (i.e., node

by the

volumetric elements a and b, respectively. As shown in

Figure 2.19, the separation is then applied

evenly in both directions from the current location of the original

node (i.e., node ![]() ). This even distribution has shown to give

good results although a mass-weighted separation can be used by which

the displacement is greater towards the lighter edge element.

). This even distribution has shown to give

good results although a mass-weighted separation can be used by which

the displacement is greater towards the lighter edge element.

![\includegraphics[scale=0.65]{nodenostretch.eps}](img218.png)

![\includegraphics[scale=0.65]{nodeprestretch.eps}](img219.png)

|

In two dimensions, the nodal separations can receive contributions from multiple

neighboring cohesive elements, and in both the ![]() and

and ![]() directions.

Figure 2.20 is a schematic example

of three connected edges where cohesive elements are inserted. We first transform

the normal and tangential cohesive separations into the separations along

the principal

directions.

Figure 2.20 is a schematic example

of three connected edges where cohesive elements are inserted. We first transform

the normal and tangential cohesive separations into the separations along

the principal ![]() and

and ![]() axes, resulting in separations of

axes, resulting in separations of

![]() and

and ![]() . When applying these separations to the various

nodes we must be careful not to simply sum the contributions from

each neighboring cohesive element. Instead we can either use the maximum

or minimum nodal separation, the average of all of the neighboring

separations, or some weighted distribution based on the mass of the

current node. After some testing we found that the optimal approach

is to use the average of the neighboring cohesive separations. The other

approaches induced greater oscillations for every test case.

. When applying these separations to the various

nodes we must be careful not to simply sum the contributions from

each neighboring cohesive element. Instead we can either use the maximum

or minimum nodal separation, the average of all of the neighboring

separations, or some weighted distribution based on the mass of the

current node. After some testing we found that the optimal approach

is to use the average of the neighboring cohesive separations. The other

approaches induced greater oscillations for every test case.

Figure 2.21 shows the effect of pre-stretching

on the separation of the cohesive node for the ![]() (0

(0 ![]() ),

), ![]() (

(![]()

![]() ) and

) and

![]() (

(![]()

![]() ) time step insertion cases for the simple 1-D problem

discussed earlier. The oscillations, while still present, have been

drastically reduced. More tests of the effect of adaptive cohesive

element insertion on the solution are presented in Chapters

) time step insertion cases for the simple 1-D problem

discussed earlier. The oscillations, while still present, have been

drastically reduced. More tests of the effect of adaptive cohesive

element insertion on the solution are presented in Chapters ![]() and

and ![]() .

.

![\includegraphics[scale=0.6]{cohsep_blindinsertwithprestretch_1d.eps}](img226.png)

|